The metal industry benefits from more agility in the supply chain and value chain. This is only achieved by bringing supply and demand together as well as possible. Matchmaking based on artificial intelligence is key. By seamlessly connecting processes, the routings that products take are becoming smarter and smarter. The question arises: which matches do you have to make? And how? You can read it in this blog.

Where would we be without matchmaking? It brings people, organizations and companies together. Just look around you, there is plenty of matchmaking going on. We know the phenomenon of dating sites, to ultimately have a happy marriage as a result. Or a fun filled night of course, let’s not beat around the bush.

We see matchmaking returning to the sport of boxing, to host an important match between world stars. In video games, to bring the right players together. Matchmaking can even save lives when characteristics of organ donors match those of recipients.

Matchmaking is also a determining factor in the business world. In the sales process, it is a crucial factor to bring in the ideal customers. The same applies to business events, for which you want to find the right visitors. To stay on the subject of entrepreneurship, you can eventually apply matchmaking in every supply chain and value chain. The challenge here is: how do you ensure that you fill the existing need (demand) as well as possible with what you can offer (supply)?

How does automated matchmaking work within the metalworking industry?

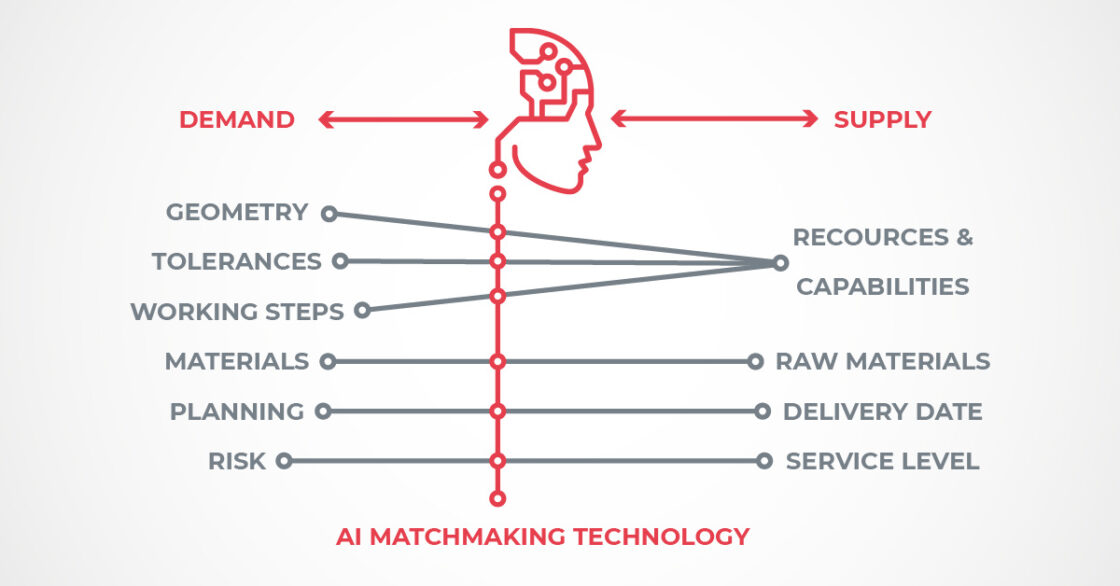

So many factors influence matchmaking within the metalworking industry that artificial intelligence is the only way to automate it. The variables too diverse for an estimator or bid preparer to achieve a 100% match. This would simply take too much time. Especially when it comes to more complex inquiries. Below are the 4 primary variables to consider when it comes to matchmaking.

- What features are requested?

If we translate this to the metals industry, you have to make various matches to achieve the optimal result. That starts with the design. As a metalworker, you have to derive features from that design in order to make the right match. The question is: which machines are capable of producing these features?

- What tolerances are acceptable?

With the features come quality descriptions. This includes: which tolerances are acceptable? What crudities are still allowed in the product? Clients record such quality descriptions in Product Manufacturing Information (PMI).

It means that as a metalworker you must be able to read out PMI data and match it with machines that can meet the requested tolerances. Then, for example, you may find that you need to add operations to get to the right level of crudity in the product. Either way, your factory and your machines need to be set up to meet the demand.

- What is the required capacity of the supplier?

This is a form of matchmaking that you can distill from drawings and specifications of the requesting party. But other data is also needed to fully and optimally apply matchmaking.

After all, you also need to know when the requesting party wants to see results and what the delivery date is that he has in mind. You have to match those requirements with how busy you already are as a supplying party. Can the assignment fit into the capacity you have?

- What risks does a production or supplier entail?

If we look from the perspective of the outsourcing party, there are always risks. You can also largely overcome these thanks to matchmaking. The supplier can demonstrate that it can meet certain service levels. Or he can show that he has already successfully performed the requested operation several times, which makes him a reliable partner.

Which smart algorithms offer a solution when it comes to matchmaking

If we look at the world of matchmaking through this lens, we see in the metals industry that it is mainly the decision-makers who make the matches. However, the accuracy sometimes leaves something to be desired. That is inherent in people’s work when so much complexity is involved. Artificial intelligence offers a solution. Now that factories are increasingly automating, they can also apply matchmaking algorithms. There are many. That is why it is useful to categorize them all. Let’s run them down.

Can you deliver what is requested?

Starting with the basic category that you need to have in order as a manufacturing factory: you need to know what you can deliver and what the customer wants to receive. The customer demand is reflected in the design. It is then important to check whether you can make matches based on your own possibilities with all those desired aspects within this design. Can you carry out the production steps required? In other words: can you deliver what is requested?

Do you have the right machines and operators?

The next question is, are your machines capable of performing the operation? Is the product to be processed not too large or too thick? Does your machine have the right tools for it? If you can answer those questions with yes, then you can look at the operation. This requires operators in most cases. Do you have operators in your workforce who can get this job done?

Once we know that – machines check, operators check – what is the occupancy rate of your machines and operators? In other words, are they available? Suppose that is only in a few months and the customer asks to deliver the day after tomorrow, then unfortunately there is no match.

What precision can you meet?

This category forces you to ask yourself the question: do you have the machines and people for it to perform the operation in the requested state of precision? And can you demonstrate to the customer that you can do this with a high degree of reliability and within the desired time?

Just an interim assessment: the harder you are to make the matches on all the factors mentioned so far, the harder you will be able to demonstrate as a factory that you can make it and deliver it. There is a good chance that the risk for the requesting party is then too high.

What is the production routing?

Then there is a completely different category of matchmaking that covers the entire production process and all the steps that go with it. Namely the question: what is the best production routing? You can also apply smart matchmaking to this by examining various steps and qualities within your factory. They determine which routing a product takes in your factory. We call this the “ilities”. Because in English they end with “ility“. We list them below.

- Loadability

How well can a product be loaded on the machine? Sometimes a robot can do that, sometimes a human is needed. Both of these affect the routing through your factory.

- Retrievability

How easy is it to pick up the processed product by a human or machine?

- Stackability

To what extent can the processed product be stacked? And does that have to be done by a human or machine?

- Manageability

How manageable is the workpiece? If it is very large or heavy, you may need a robot or several people for it.

- Storability

How easily can you store the processec product in the warehouse? Does it take up a lot of volume? Is it flat? All affect the final match.

- Measurability

To what extent are the features in the processed product accessible for measuring instruments? The same applies to your pressing equipment and screw device: the product must have a shape that you can reach with it.

- Packability

Once the operation has been completed, the product must be sent to the customer. Then you have to pack it first: how easy is that to do?

- Transportability

Then the product has to hit the road. How big or fragile is it? In other words, how transportable is it?

These are all factors that you can express on a scale: from very easy to very difficult. Thanks to all these matchmaking algorithms, you can determine whether or not you should accept an assignment as a metalworker. And if you don’t want to or can’t do it yourself, you can easily use these algorithms to see which supplier would match.

Are all purchased parts and raw materials available?

This was all about matchmaking between what is desired and what you can do as a metalworker – and looking at it from all kinds of stages in the production process. The next category is matchmaking with the suppliers and you as a metalworker. Can they supply the purchased parts and raw materials that you need to perform an operation? You will have to match: which supplier is the best in terms of the materials (and the quantity and speed) you need?

In times of changing prices and a stagnant supply chain because it is not certain who can supply what, the complexity of this form of matchmaking increases, and with it the importance of optimizing it.

Which operations can or should be outsourced?

On to the next category: outsourcing operations. In fact, you do the same as when you apply matchmaking within the walls of your own factory, looking at the quality, capacity and availability of your machines and personnel. But now you want to take a look inside the other person’s factory.

You also want to use matchmaking on this, so that you can outsource an operation to a party that can do it well, is sufficiently reliable and can deliver within the required time — because your own delivery time is related to this.

Can you anticipate setbacks such as machine failure?

Not only metalworkers, OEMs also benefit from knowing which factories can do what. They also want to be able to apply matchmaking, so that they can choose the best combination of suppliers. This has traditionally been done by the procurement department, which enters into contracts with suppliers and makes agreements.

In modern times, you want to be able to anticipate immediately when things go wrong, for example if a supplier has to deal with machine failure, by finding a replacement solution in the market. Preferably on an intercontinental level: matchmaking across borders.

A dynamic supply chain requires artificial intelligence

If metal plants can do that, the supply chain becomes much more dynamic. After all, they switch between suppliers much more often and can therefore respond much more quickly to negative events. When the supply chain gets that agility, you as a supplier have to make sure that you have your organization in order to be able to participate in that game. And so you will have to digitize.

Those who optimize matchmaking and automate on the basis of artificial intelligence can choose their production routing more intelligently. Smarter means: optimum quality at the highest possible efficiency and reliability.

To do this, first start by optimizing the routing within your own factory, then do this with the routing of your suppliers of raw materials and purchasing parts and then with the routing of the parties to which you can outsource processing. Finally, if OEMs also make use of this, both the supply chain and the value chain will become more optimal and agile with every stroke.

The way forward is clear – automated matchmaking using AI is key.